Misaligned kiln axes are a major cause of reduced kiln efficiency and shortened equipment life, making early detection and correction essential. Kiln Service Europe provides hot kiln alignment services to correct axis misalignment without extensive shutdowns. A misaligned kiln axis can overload supports and bearings, placing excessive stress on the kiln shell and tyres.

During hot kiln alignment or inspection, the kiln axis is measured with highly accurate methods and the latest precision tools. To address the root cause and extend the life of critical components, Kiln Service Europe evaluates the kiln axis and, if necessary, aligns it by adjusting the supporting rollers.

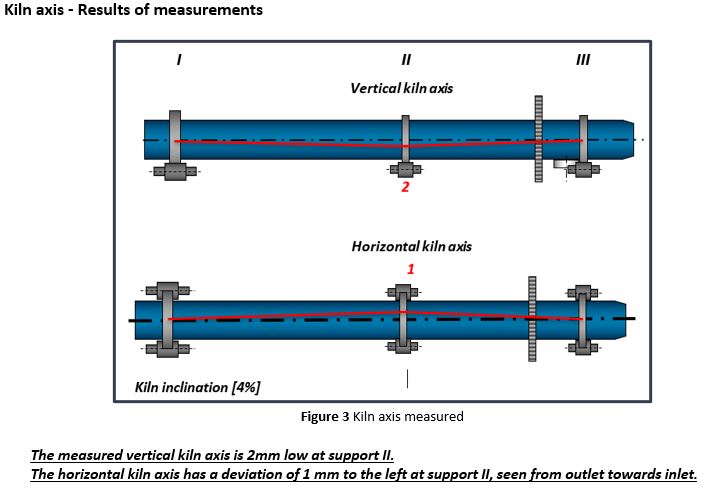

Kiln Axis

We provide precise, detailed assessments of your kiln axis and, if needed, we perform adjustments immediately at the end of the inspection.